|

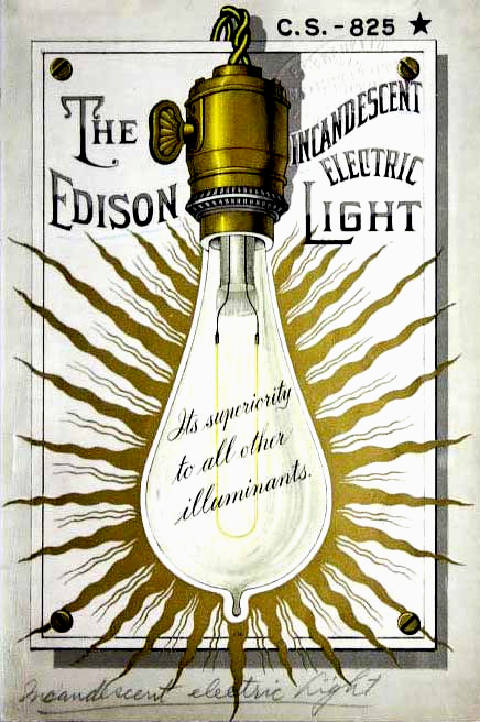

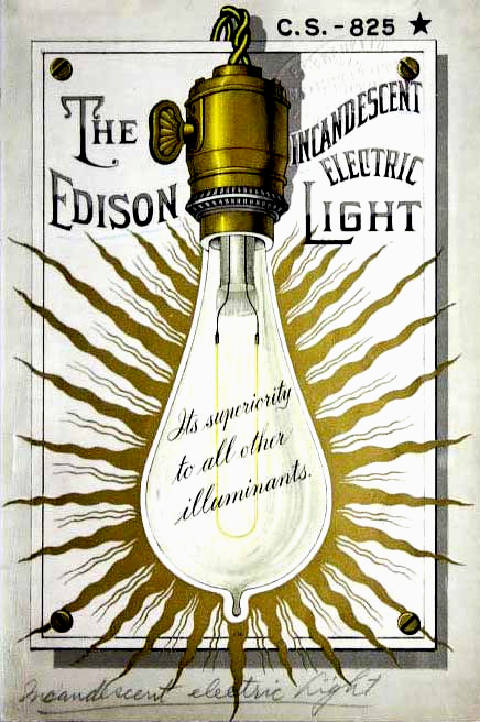

Thomas Edison began serious research into developing a practical incandescent lamp in 1878. Edison filed his first patent application for "Improvement In Electric Lights" on 14 October 1878. After many experiments, first with carbon in the early 1880s and then with platinum and other metals, in the end Edison returned to a carbon filament. The first successful test was on 22 October 1879, and lasted 13.5 hours.

Edison continued to improve this design and by 4 November 1879, filed for a US patent for an electric lamp using "a carbon filament or strip coiled and connected ... to platina contact wires." Although the patent described several ways of creating the carbon filament including using "cotton and linen thread, wood splints, papers coiled in various ways," Edison and his team later discovered that a carbonized bamboo filament could last more than 1200 hours. In 1880, the Oregon Railroad and Navigation Company steamer, Columbia, became the first application for Edison's incandescent electric lamps (it was also the first ship to use a dynamo).

In Britain, the Edison and Swan companies merged into the Edison and Swan United Electric Company (later known as Ediswan, and ultimately incorporated into Thorn Lighting Ltd). Edison was initially against this combination, but after Swan sued him and won, Edison was eventually forced to cooperate, and the merger was made. Eventually, Edison acquired all of Swan's interest in the company. Swan sold his US patent rights to the Brush Electric Company in June 1882.

The United States Patent Office gave a ruling 8 October 1883, that Edison's patents were based on the prior art of William Sawyer and were invalid. Litigation continued for a number of years. Eventually on 6 October 1889, a judge ruled that Edison's electric light improvement claim for "a filament of carbon of high resistance" was valid.

In 1896 Italian inventor Arturo Malignani (1865–1939) patented an evacuation method for mass production, which allowed obtaining economic bulbs lasting 800 hours. The patent was acquired by Edison in 1898.

In 1897, German physicist and chemist Walther Nernst developed the Nernst lamp, a form of incandescent lamp that used a ceramic globar and did not require enclosure in a vacuum or inert gas. Twice as efficient as carbon filament lamps, Nernst lamps were briefly popular until overtaken by lamps using metal filaments.

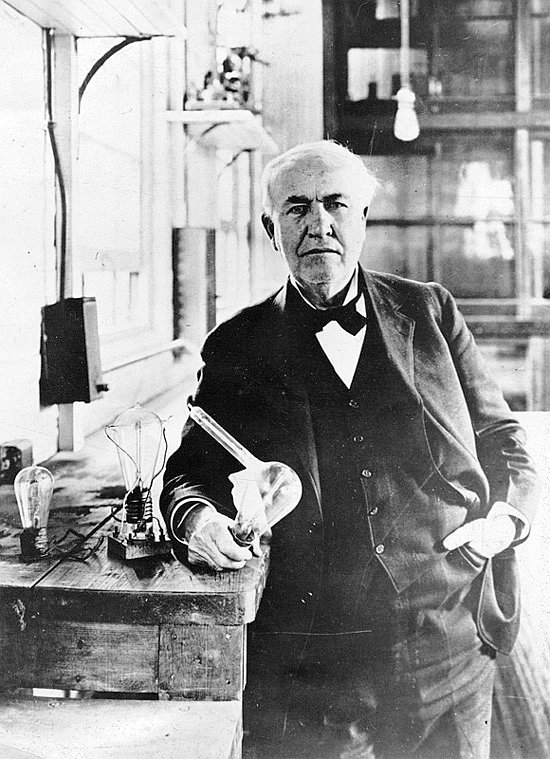

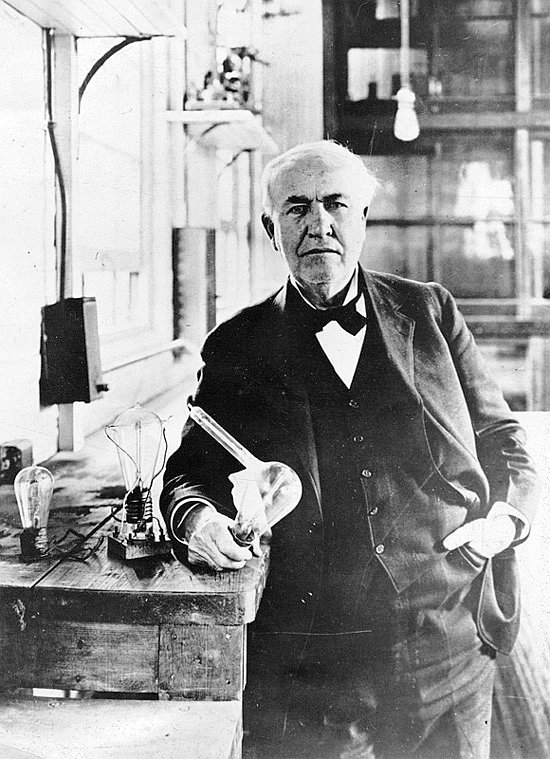

There

are several great and famous engineers and inventors, involved with

Major Charles de Roemer, in the development of Herstmonceux Electricity

Works. The Major, himself, being no slouch in engineering and

entrepreneurial endeavor. Thomas Alva Edison was one of those touching

base with the Major, because of the electrical lighting, switch and

control gear he chose to install, and because Charles de Roemer was

leading the rural socialite charge to resistance illumination, while Thomas

was working on his generating station at Pearl Street, in New York,

producing generating apparatus, and generally pushing his incandescent,

carbon filament, glass bulbs - for all he was worth.

But,

what really brought the two together, was Joseph Swan, the English

physicist and inventor of the light bulb. Developed in the UK, independently of Mr

Edison in the US. As was to be unraveled in the High Court in London.

Ending in the Ediswan Lighting Company; a joint venture, by Order

of the Court. Such as not to invalidate the US patent. Since, technically,

Joseph Swan was first.

The

Major was also acquainted with John Hopkinson, another well known

British electrical engineer. It was a sort of an 'Electrical Club.' Thus, when

Thomas Edison was in England to have a litigation bash with Joseph Swan.

It was natural for the social elite to gather at the Manor House in Lime

Park, where much entertaining was done. According to Margaret

Pollard's fascinating account of her life as a young lass growing up

in the village of

Herstmonceux.

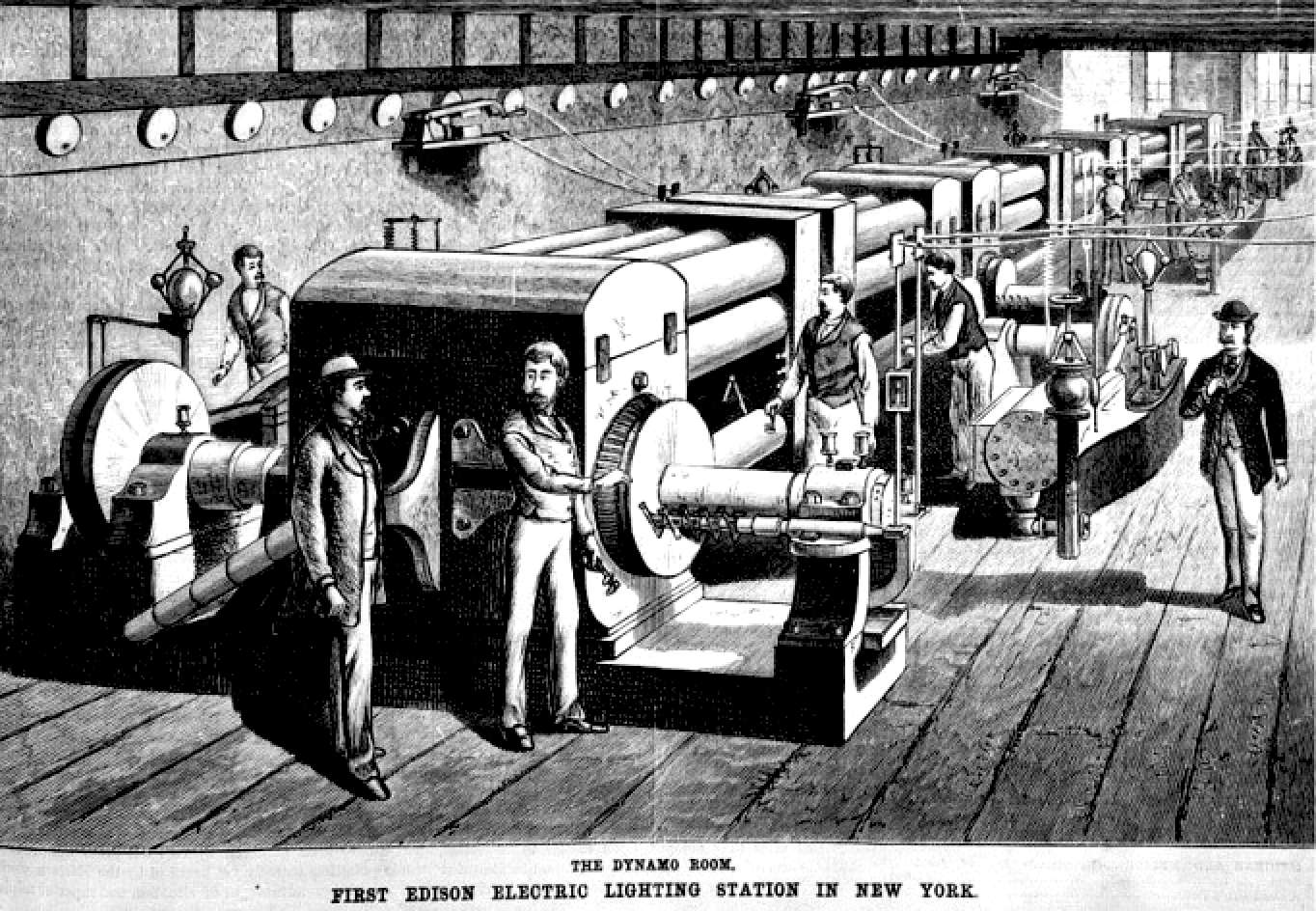

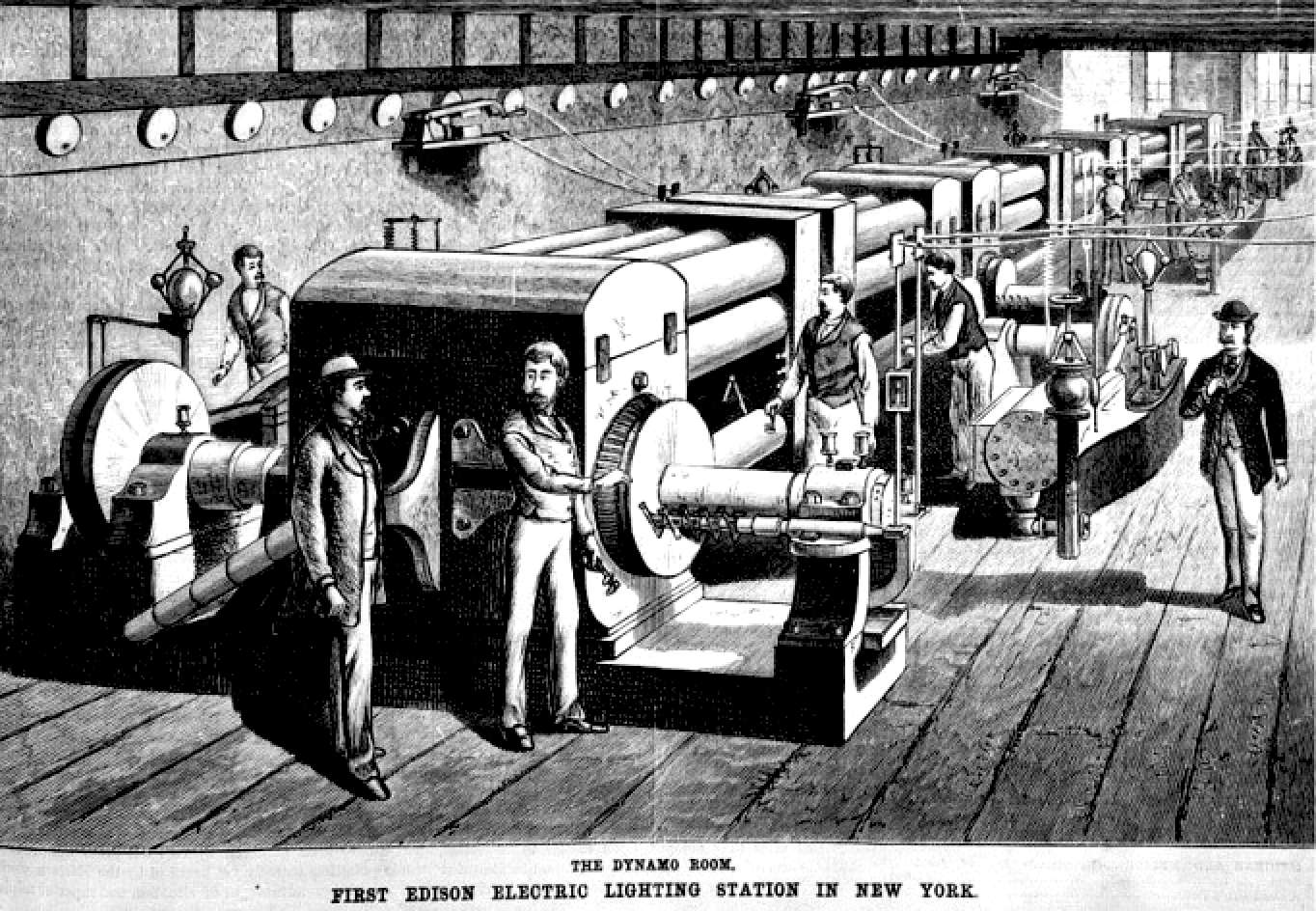

An

illustration of the first Edison electric lighting station in New York,

showing the dynamo room.

During the early 19th century, natural gas, kerosene, and whale oil all provided fuel for lighting homes and businesses. In particular, the gas industry had invested in extensive pipe infrastructure to light offices, public institutions, streets, and homes. Though widely used, these methods were dirty and dangerous, and their light wasn’t much stronger than the flame of a candle.

While many scientists worked on viable ways to manufacture and store electric energy, Sir Humphry Davy began demonstrating so-called “arc lamps,” which create a brilliant curve of electric light in the air between two electrodes, or carbon rods. Davy also experimented with the process of incandescence, whereby an electrical current passing through a wire filament makes it hot enough to glow. However, since arc lighting was around 200 times brighter than incandescents, the former quickly became the most likely contender for a modern light source.

Davy wasn’t interested in turning his experiments into commercial products, but others certainly were. An American named Charles F. Brush had tweaked the arc-lamp design to create a cheaper and more reliable electric light, along with an improved dynamo, or electric generator, both of which he unveiled by lighting Cleveland’s public square in April of 1879. On July 4th of that year, Brush used 16 arc lamps to light Niagara Falls, a feat that one paper mistakenly reported was accomplished by Edison (who was famously known as the “Wizard of Menlo Park” for his work on the telegraph and phonograph at his lab in Menlo Park, New Jersey).

The following year, the Brush Electric Company began selling 16-lamp sets of these impressive arc lights and their requisite generators. Because they were so bright, the lamps were mostly used in huge factories, retail settings, or outdoor public spaces like the Great White Way, an illuminated section of Broadway between Madison Square and Union Square in New York City. Their most obvious benefits were seen in industrial spaces, where electric light increased potential production hours into the night, yet also improved employee safety.

Though arc lighting was undoubtedly an improvement, people felt it had a harsh, unearthly glow when compared with gas lamps, and doctors warned of the dangers electric light might have for one’s health. As a result, some manufacturers adopted white globes of opal glass to cut the brightness. In order to woo supporters, electric companies often promised cities a year of electric lighting at the same price as their previous gas fees, so places like San Jose, Los Angeles, and Detroit led the way by installing arc lamps far above their streets on so-called “moonlight towers,” named after their omnipresent glow. (Austin, Texas, is the only American city whose original moonlight towers still stand.)

After a trial run, many realized that electric light was pricier than gas, but residents were willing to pay for the improved light and its purported safety benefits. Others simply wanted to maintain their town’s relevance after neighboring municipalities adopted the technology.

Even as arc lighting spread, everyone was following the development of incandescent lamps, especially executives at the all-powerful gas companies. Edison continued to tantalize the press with hints of the electrical innovations happening at his famous lab, but the perfect light bulb still eluded his team of

researchers.

There were four major issues with electric light that scientists like Edison were attempting to tackle, the first being which material made the best filament. In the late 1870s, the English physicist Sir Joseph Wilson Swan had built a working incandescent prototype using carbonized sewing thread as a filament. Within a few years, Swan’s home became the world’s first to be outfitted with incandescent bulbs (Swan’s American patents were later acquired by Brush).

Edison initially tried a platinum design, moving on to a longer-lasting carbon filament invented by Lewis Latimer, an African American scientist hired to work in Edison’s laboratory. As Jenkins explains, “they ended up taking Bristol board, a kind of cardboard, and stamping it out in a horseshoe shape that would be baked in an oven overnight, turning it into carbon. Then using jeweler’s tools, Edison’s technicians would secure it in a couple of tiny clamps inside the lamp.”

The second major hurdle involved protecting the filament from oxygen in the air so it wouldn’t overheat and burn itself up; this was accomplished by sealing it inside a vacuumed chamber created in a clear glass bulb. To improve his vacuum technology, Edison sought out a German glassblower named Ludwig Boehm, who had been making Geissler tubes (a predecessor to neon lights), which required a special mercury vacuum pump. The pump was made from a glass cylinder more than 6 feet tall and a few inches in diameter, divided in half by a valve. With the valve closed, mercury would be poured into the top half, which was connected to the light bulb via a small hose. To evacuate the lamp, you’d open the dividing valve, and as mercury flowed into the bottom half of the cylinder, it would create a powerful vacuum, sucking the air out of the light bulb.

Even if properly vacuumed, impurities in a filament tended to darken the inside of a bulb. After being used a little bit, the inside of the lamp would turn black. We're sure you have all noticed that, even in some modern halogen bulbs.

Edison’s lab came up with the idea of running a current through the filament while the vacuum was being drawn off, burning the impurities off and sucking them out with the vacuum pump. That process helped prolong the brightness of their bulbs.

The final problem was preventing the wires connecting the filament to a power source from cracking the glass bulb near their point of entry. As the glass heated and cooled around those wires, it would crack and destroy the vacuum, dramatically reducing the life of these lamps. Edison’s first bulbs only burned for around 15 hours, so it wasn’t an issue for those. Later, his researchers realized that the electrical resistance of platinum is significantly lower than copper, so there is much less heat produced. They figured if they used platinum, there would be less expansion and contraction, so maybe they wouldn’t crack. Sure enough, platinum lead-in wires solved the problem.

While these experiments with incandescent bulbs were taking place, many of Edison’s employees were also working to build a more efficient electric generator to power these lights. In late 1879, Edison finally opened his lab for a public demonstration of a new incandescent light bulb with a carbonized-cardboard filament, illuminated by a new kind of generator. Visitors were mesmerized by the soft glow of Edison’s lamps, describing them as “little globes of sunshine” and noting the distinct absence of smell. Though other inventors were skeptical of Edison’s electric-lighting technology, natural gas stocks plummeted after the big reveal.

New companies were joining the booming electrical market every year, resulting in a highly competitive environment for electrical patents and a mess of copyright infringement lawsuits. Scientists like William Sawyer, Albon Man, and Sir Hiram Maxim were also securing their own electrical patents, but the design limitations of their inventions often inadvertently aided Edison’s team.

It is because none of these inventions were entirely successful, that we have Edison’s name in the encyclopedia, and you learn about him in the fourth grade instead of Swan or Maxim.

In 1881, the International Exposition of Electricity in Paris was a culminating point for the leading inventors working on electric lighting. In addition to examples of his work on the telegraph, telephone, and phonograph, Edison installed a gigantic display featuring incandescents made with carbonized-bamboo filaments, powered by the world’s largest dynamo. “Edison’s company displayed its lights on the exhibition hall’s grand staircase, where visitors encountered two massive electrified E’s, and a huge portrait of the inventor that revolved under a spotlight,” writes Ernest Freeberg in his book, The Age of Edison. “And so the first person to see his name ‘up in lights’ was Edison, because he put it there himself.”

Though Edison wasn’t the first to create a working incandescent bulb, he did conceive of a more complete electric-lighting system, from power generation through a set of parallel circuits that could be subdivided among buildings and finally connected to switches controlling incandescent lamps in the home or workplace. Edison didn’t just develop a lamp; he invented a whole system of creating and delivering electricity, including the dynamos, the wiring, the way of measuring the current, and the lamps themselves. Edison had soon established a group of companies that would manage each element of the process, making his arrangement the most obvious challenger to the gas-company empire.

Edison was a cunning businessman with a knack for self-promotion, and he worked to make his name synonymous with electric power.

After the Paris exhibition, the electric-lighting industry exploded. At first, only the wealthiest could afford to adopt electricity in their homes, and even they only installed it in certain rooms. In the 1882, three years after Edison’s first incandescent light bulb, if you had the money to get one area of your house electrified, that’s what you did. You bought a generator system, and somebody came out and wired it for you and installed an electric light fixture somewhere in your home. But you didn’t jump right in, and suddenly have lights in every room in your house. It's something like solar power, with roofs partially fitted with panels, and experts coming out to install them for you.

Generally, customers would purchase entire electrical systems manufactured by a regional supplier who would handle installation and upkeep. If a bulb “burned out,” someone would come and replace it for you. In the 1880s, if you had an electric system installed, whether it was a business or a residence, the manufacturer took care of everything. Charging separately for lamps didn’t come until a little bit later.

Instead of throwing away an entire bulb when it went out, the base was usually reused with a new filament and glass envelope. They would remove the base from the burned-out bulb, put new glass in it, connect the wiring back together, and reset it using plaster insulation. Because of this, bulbs were designed to last as long as possible, rather than a limited number of hours. From the beginning, from the invention of the carbonized filament light bulb, all companies were working on a version that would last forever. But with the invention of screw bases and bayonet fittings. It was more how do we make them cheaper and make them burn out so they have to buy more? Repeat buisiness effectively halted the search for the everlasting bulb.

The sturdy quality of antique bulbs makes some appear nearly indestructible, like the “Centennial Bulb” in Livermore, California. Made by the Shelby Electric Company, the Centennial Bulb is still burning after 114 years. Shelby is one of the companies that pioneered the tipless bulb, and their bulbs are known to have indestructible filaments.

In 1882, Edison one-upped his competitors by completing the world’s first central power plant, Pearl Street Station, in lower Manhattan. The facility used coal to power several blocks of businesses, including the headquarters of several major newspapers and banks, plus the private homes of elite residents like William Henry Vanderbilt and J.P. Morgan. The project was an unparalleled success, and Edison set about replicating the system in every major city in America.

Brighter electric lighting was applauded not only for eliminating most of the grime generated by gas and coal, but also as an antidote to crime through its supposed ability to expose inappropriate behavior after dark. Although electrical systems had their own fire issues due to faulty wiring, on the whole they were viewed as safer than the existing infrastructure of gas pipelines and smoky, flame-filled lamps.

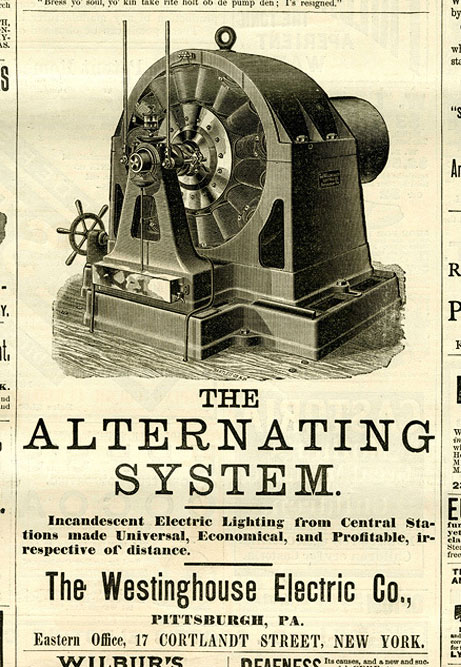

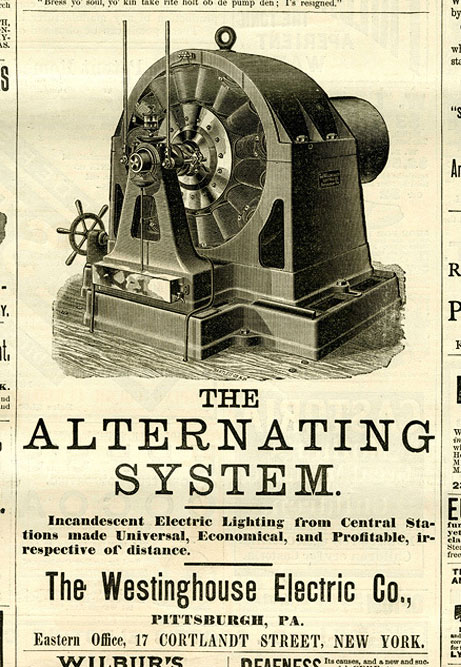

The density of urban areas also meant the limited reach of Edison’s direct current (DC) system wasn’t an issue, though power stations with heavy, expensive cables would need to be built every few blocks. However, by the late 1880s, George Westinghouse’s alternating current (AC) system was a looming threat to Edison, as it could distribute power over hundreds of miles (and would eventually replace the DC model). The battle between Edison and Westinghouse became known as the “War of Currents,” which Edison fought by spreading misinformation on the dangers of AC power, even going so far as to design the world’s first electric chair using an AC system in order to tarnish its reputation.

Just like the cutthroat world of technology today, the electric industry was awash with industrial espionage, as upstart companies were acquired by a few giants (like when the Thomson-Houston Electric Company bought Brush’s pioneering business in 1889) and patent rights were purchased or challenged (Westinghouse bought several of Nikola Tesla’s patents, including many related to AC generation, even though Tesla had briefly worked for Edison). In order to avoid patent infringement and ensure their products weren’t interchangeable with their rival’s, major companies used different electric lamp designs. “The bulb, the bulb base, the socket that it fit into, the wiring receptacles—all of those would vary depending on the manufacturer.

The incandescent bulbs that first brightened people’s homes and workplaces looked only slightly different than the incandescents we know today. “Edison’s original lamp and its descendants were produced by heating and blowing into 1-inch-diameter glass tubing,” says Jenkins, “which would naturally take on a bulbous shape, like a baseball sitting on top of a tube.” Other bulbs were made with elongated glass envelopes in order to fit the longest possible filament, since developers believed that would produce a brighter light. On all early bulbs, the glass envelope was tipped with a small point left by the vacuum process, a feature that was later eliminated by vacuuming nearer to the base.

PATENT APPLICATION 1878 No. 223.898 - ELECTRIC LAMP - THOMAS A. EDISON

T. A. EDISON. Electric-Lamp. Patented Jan. 27, 1880. UNITED STATES PATENT OFFICE. (NOTE: from imperfect archive document)

Let is be known that I, Thomas ALVA Edison, of Lincoln Park in the State of New Jersey, United States of America have invented an Improvement in Electric Lamps, and in the method of manufacturing, (Que No. 86,) of which the following in my specification.

The object. of this invention in to produce clear lamps giving light by incandescence, In which lamps shall have high resistance, 06 on no cllow of the practical subdivision o! the electric light,

The inventlon co in n light giving body of carbon who or about: 00' ad or arranged in i and: n manner as no 050: m miownco to the of the electric current, and et the limo time percent but o alight carbon from which radiation can take place.

The invention further consists in placing no such nrncr 0! great rcnin'zonoo in a near vacuum to prevent oxidation and innrymo the conductor by the atmosphere. The 2 is conducted into the vacuum-bulb Qhmgh plctlno via-cu sealed into the glam. :5 The invention In other oonniatnin the method 0! manufacturing carbon conductor: 01' high soon to bc nnitnblo for giving light by incandescence, and in the manner of making perfect contact between the metallic conductors or leading wvim and the when conductor.

Hunt for light by incandescence has been Obtained from rods of carbon of one to' four ohms resistance, placed in cloned vcmcln, in which the atmospheric air has been replaced bygone: the: do not combine chemically with carbon. The vcnnel holding the burner tmcomponod oi grim oomontcd to a mo- -"C base. The connmtion Waco the lead- 4 "I n: and the cerbin has wen obtain-d b! p g the carbon to tho mm. Tho 02dlug-vim have always boon largo, no that. their rmlotnnoc shall bo many times loss than tho in general, the nttcmptn of pre- 5 vionn pcrnonn have buen torcdnm U10 olthc mrbon rod. The diaadven tngcn of follow in: this preetioo m that. a lamp ha hm Onctoionr ohms miatnncc cannot be vorkcd in Mt numbers in multiple on: without. the em- 5 F ament of main conductors of enormous dim; than, owing to the low rrniatnnoo of mp, Else lmlm mm must be 0! m dimension-no good conductors, and n l.- globc cannot be kept tight. ct the plncn 1r era the wimpin cod no cemented; honon tho urban iuconnnlnod, bccnnno there must ho n1- mont o perfect vacuum to render the carbon stable, onpccinlly vhencnch carbon inuncll in mnndhi hin electrics! rcslnunon.

Thcnaoo gun in the rconivcrn than:- do monpbcrio prcmure, although M min: the carbon, ncrvcn todcnu-cy it in time by air washing," or the nutrition produced by the rapid of tho air over the slightly-o0- hcront. highly-heated nnrlacc of the when. I have reversed this practice. I have discovered that even a cotton thread properly rnrbonlw and placed in one glass bulb oxhanotod to one-millionth of an atmosphere offer. from one hundred to live hundred ohms renintlnuc to the pun-n50 of the current. and that. it lnnblolutoly stable at very high tempertures; thsz ll the thread bo coiled no a spiral and carbonized. or if my fibronn vegetable cnbntnnoc l will learn a carbon ruidnc after heating in 5 cloned chamber be no coiled, so much an tI0 .thonnend ohm: reoinunoc moy be obw fl without presenting n rndinting'nnrlnco greater than tbrco-lixtecnthn of m inch; tnu. f each fibrous materiel be rubbed with nplut c 00 l poood ol' Imp-black and tar, its resistance :my bo mode high or low. according to amount of lamp-block placed upon it; that en!- bon fllnmcntn mar be made by n oombln of tor and lamp-black. tho lager being 1" vionaly ignited in o closed crucible for loverll l honrn and clherwnrd moistened and kneaded until it makes the consistency of thick putty. Smell picou of this material any be rolled out in the form of vire a small on ncven one-thousandth of an inch in diameter and over a foot in length, and the name my 5.

l W with n non-conducting non'cerbonlzln; nabs-anon and wound on n bobbin, or u n I!- and the tor cnrbonizcd in a cloned chowl her by subjecting it to highland-l m 'P'" nl'ur carbonizntion rculning It. form. be All than forms are l'rngilc nnd cum; "I, clamped to the lending wirm 'dh outlier; loroc to insure good contact and prevent h ing. 1 have diamond that if platinum: are used and tho plulic lamp-block on matorinl be molded mound it. in the auto. on mtion there in nu intimnle union bycon- EST AVAILABLE COPY material be molded around it in the act of carbonization there is an intimate union by combustion and by pressure between the carbon and platine, and nearly perfect contact is obtained without the necessity of clamps; hence the burner and the lending-wires are connected to the carbon ready to be placed in the vacuum-bulb.

When fibrous material is used the plastic lamp-black and tar are used to secure onto the platina before carbonizlng.

By using the carbon wire of such high resistance l mu enabled to use fine platinum wires for leiuling' wires, as they will have a small resistance compared to the burner, and hence will not limit and crack the sealed vac uunl-bulb. llatinu can only be used. no its expansion is nearly the same as that of glass.

By using a considerable length of carbon wire and coiling it the exterior, which Is only a small portion of its entire surface, will form the principal rndiuting-substance; hence I am able to raise the specific heat of the whole of the carbon, and thus prevent the rapid reception and disappearance of the light, which on a plain wire is pn-judicial, as it shows the least unsteadiness of the current by the flickering of the light; but it the current is steady the defect does not show.

I have carbonized and used cotton and linen thread, wood splints, papers coiled in various ways, also lamp-black, plunibago, and carbon in various forms, mixed with tar and kneaded so that the same may be rolled out into wires of various lengths and diameters. Each wire. however, is to be uniform in size throughout.

It the carbon thread is liable to be distorted during carbonization it is to be coiled between a helix of copper wire. The ends of the carbon or filament are secured to the platina leading-wires by plastic carbonisable material, and the whole placed in the carbonizing-chanr bar. The copper, which has served to prevent distortion of the carbon thread, is afterward eaten away by nitric acid and the spiral soaked in water, and then dried and placed on the glass holder, and a glass bulb blown over the whole, with a lcadin -tuhe for exhaustion by a mercury-pump. is tube, when a high vacuum has been reached, is hermetically sealed.

With substances which are not great] (listorted in carbonising, they may be cost with a non-conducting non combustible substance, which allows one coil or turn of the carbon to rest. upon and be supported by the other.

In the drawings, ignre 1 shows the temp sectionally. n is the carbon spiral or thread. c c are the thickened ends of the spiral formed of the plastic compound of lamp-block and tar. d rl'are the phttina wires. Ii 5 are the clamps, which serve to connect the platina wires, e wanted in the carbon, with the leading-wiles x z, sealed in the glass vacuum bulb. c c are copper wires, connected just outside the bulb to the wires 2: :r. a is the tube (shown by dotted lines) leading to the vacuum-pump, which, after exhaustion, is hermetically sealed and the surplus removed.

Fig. 2 represents the plastic material before being wound into a spiral.

Fig. 3 shows the spiral alter combustion, ready to have a bulb blown over it.

CLAIMS

1 claim as my invention- I. An electric lamp for giving light by incandescence, consisting of a filament of carbon of high resistance, made as described, and secured to metallic wires, as set forth.

2. The combination of carbon filaments with a receiver made entirely of glass and conductors passing through the glass, and horn which receiver the air is exhausted, for the purposes set forth.

3. A carbon filament or strip coiled and connected to electric conductors so that only a portion of the surface of such carbon conductors shall be exposed for radiating light, as set forth.

4. The method herein described of securing the platinum contact-wires to the when filament and cerboniain of the whole in a closed chamber, substantially as set forth.

Signed by me this 1st day of November,

THOMAS A. EDISON.

Witnesses: B. L. Gun-rm, Jens F. Rmnoum.

Order of Cancellation of Certificate of Correction of Letters Patent No. 223,898.

Correction in Letters Patent No- 223 (NOTE: imperfect archive document)

Herstmonceux Museum in

2016-17, match boarding revealed, with the well head reinstated, some

tree work still needed to ensure survival of the historic buildings.

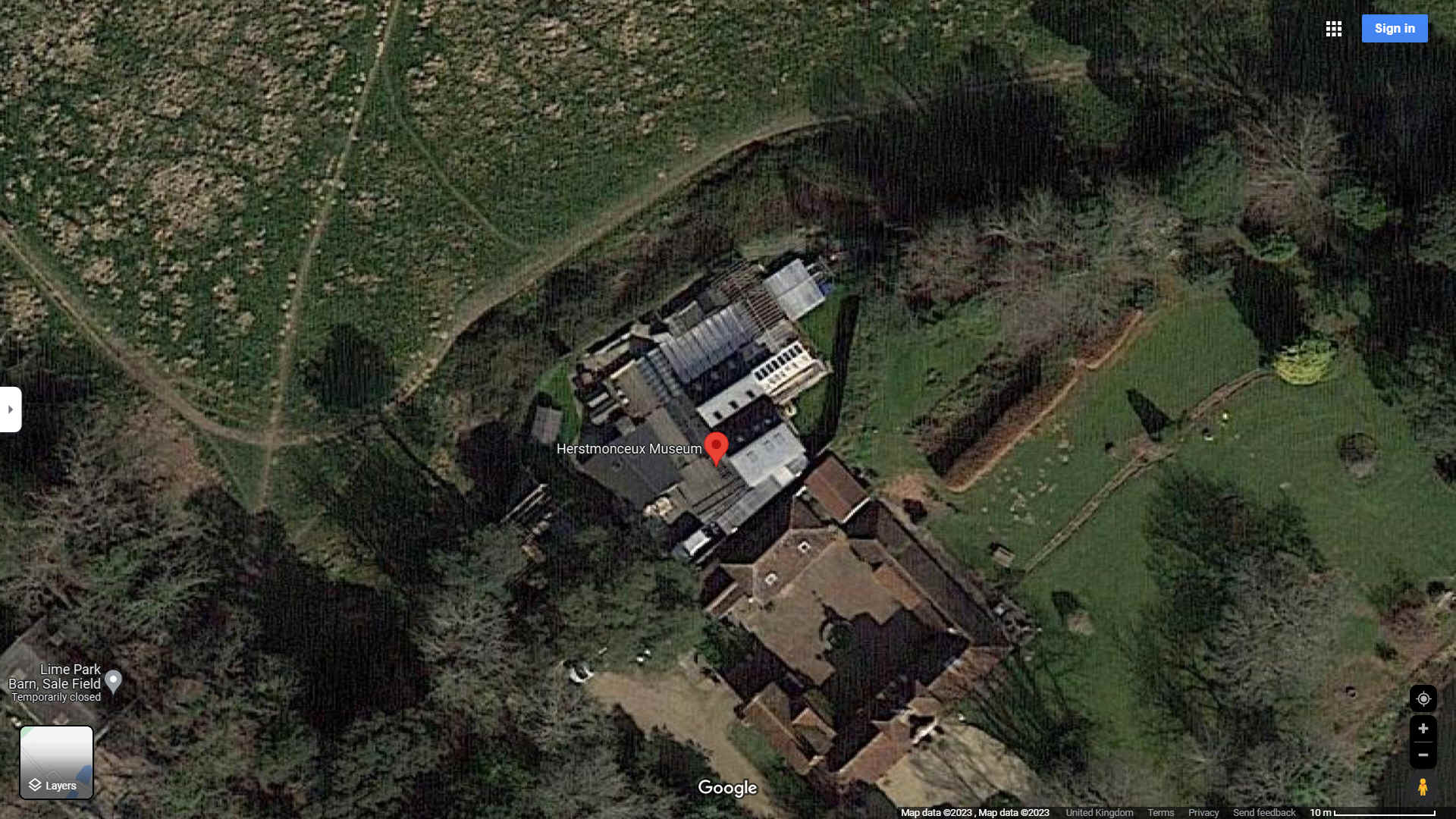

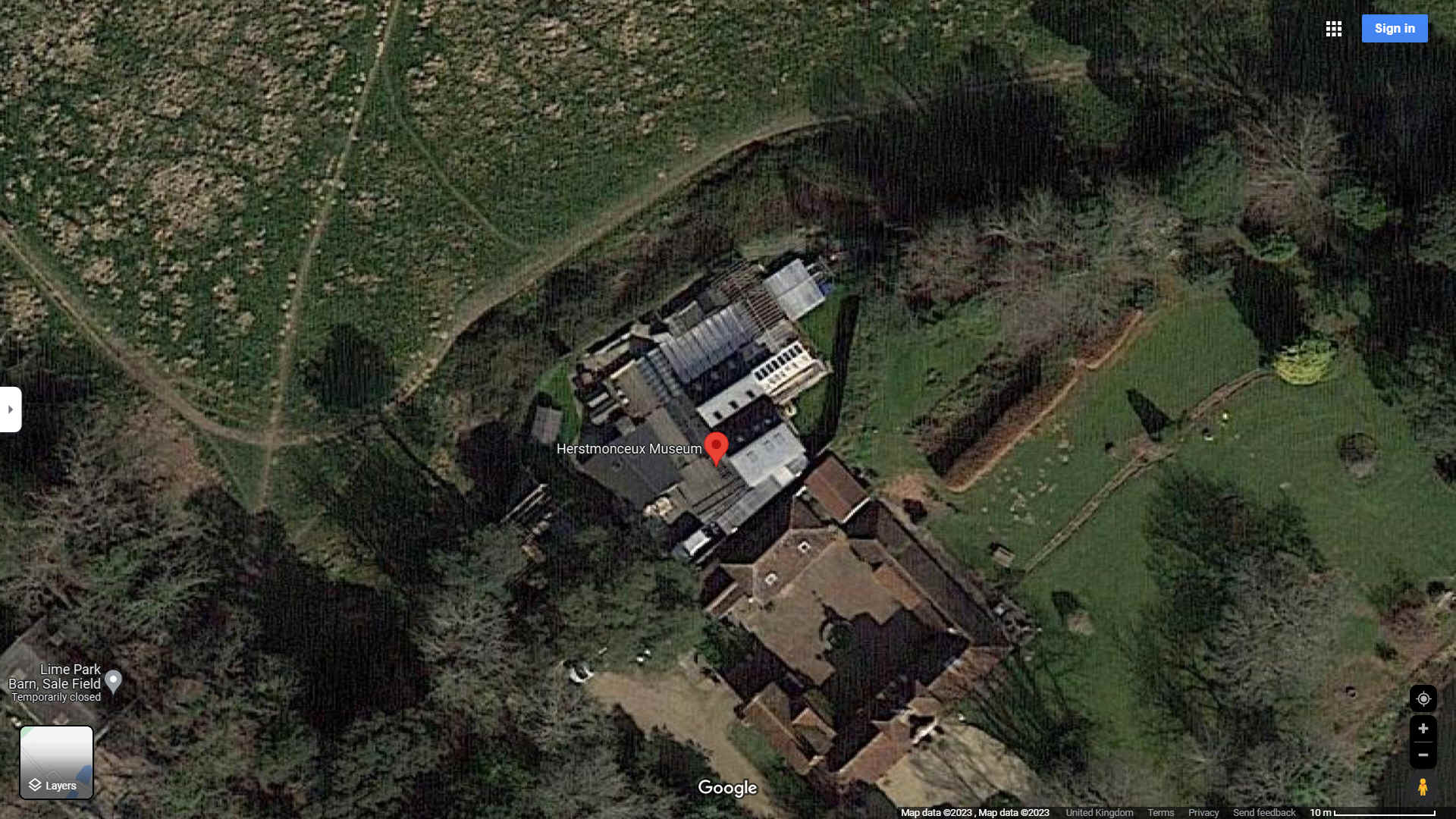

An

aerial view of Herstmonceux Museum in 2022, showing the public footpaths

north of the generating buildings. Many of which are unregistered, but

well trodden for over forty years, from our records.

LED LIGHT EMITTING DIODES

Oh yes, it gets better ..... Thomas would have loved this. in the 1980s light emitting diodes were developed of increasing size and efficiency for the electronics industry, until by 2020 they were used for industrial, domestic lighting and automotive headlights, all but supplanting the incandescent light bulb.

https://

CHARACTERS

If

you know of any information that may help us complete this story, please get in

touch.

|